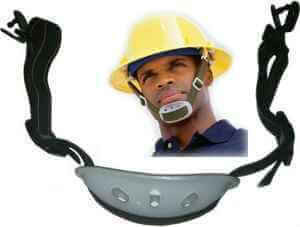

Type II Climbing Safety Helmet | ANSI Z89.1 | Full Impact Protection

The Type II Climbing Safety Helmet delivers superior protection and versatility for construction crews, tower climbers, utility workers, and confined space professionals who work in high-risk environments. Engineered to meet ANSI Z89.1-2014 Type II and Class C standards, it offers top and lateral impact protection, safeguarding against blows from all directions—top, front, side, and rear.

For example, utility lineworkers climbing poles, or maintenance crews operating at heights on scaffolding, benefit from the reliable 4-point chin strap that keeps the helmet securely in place during falls, slips, or sudden movements.

The lightweight ABS shell combines industrial climbing helmet durability with work-at-height helmet comfort, while the EZ-click adjustable ratchet system ensures a custom fit for all head sizes (6.5 to 8). Multiple accessory attachment points accommodate earmuffs, face shields, and headlamps—making it the perfect Type II hard hat with chin strap for dynamic job sites. A soft, padded antimicrobial liner wicks sweat and keeps you cool in hot conditions.

Clear/tinted visor and earmuff attachments sold separately.

Key Features:

-

ANSI Z89.1-2014 Type II, Class C Certified – Top and lateral impact protection

-

Industrial Climbing Helmet Design – Lightweight ABS shell for strength and airflow

-

4-Point Chin Strap with Magnetic Lock – Secure fit for work-at-height safety

-

Multiple Accessory Attachment Points – Compatible with earmuffs, visors & headlamps

-

EZ-Click Adjustable Ratchet System – Fits head sizes 6.5 to 8 securely

-

Soft Antimicrobial Liner – Wicks sweat, keeps wearer cool and dry

-

Ideal for Construction, Utilities & Confined Space Work – Built for industrial job sites

-

Individually Packaged – Retail-ready box presentation

FAQ

Q1: What is a confined spaces helmet?

A: A confined spaces helmet is a specialized safety helmet designed to protect workers operating in tight or restricted spaces, such as tanks, tunnels, silos, or underground chambers. It provides impact protection, visibility, and often compatibility with additional PPE like headlamps and respirators.

Q2: Who needs a confined spaces helmet?

A: Any worker entering or working in confined spaces, including utility workers, construction crews, maintenance personnel, industrial plant operators, and emergency responders. These helmets are essential for compliance with OSHA and other workplace safety standards.

Q3: What are the key safety features?

-

High-impact shell: Protects against falling debris and accidental bumps.

-

Adjustable suspension system: Ensures a secure, comfortable fit.

-

Attachment points: For accessories like headlamps, visors, face shields, or respiratory masks.

-

Ventilation: Optional vents to improve airflow in hot, enclosed areas.

-

Electrical resistance: Some models provide insulation against low-voltage electrical hazards.

Q4: Are these helmets compliant with safety standards?

A: Yes. Most confined space helmets comply with ANSI Z89.1, OSHA, and sometimes EN 397 / EN 12492 standards, depending on regional requirements. Always check the product certification before purchase.

Q5: Can I use it with other PPE?

A: Absolutely. Confined spaces helmets are designed to be compatible with:

-

Safety goggles or glasses

-

Respirators or gas masks

-

Face shields

-

Hearing protection (ear muffs)

Q6: How do I adjust the helmet for a secure fit?

A: Most helmets feature:

-

Ratchet or pin-lock suspension systems to adjust head circumference

-

Chin straps to secure the helmet in tight spaces or when climbing

-

Optional padding for added comfort

Q7: How do I maintain and clean a confined spaces helmet?

A:

-

Clean with mild soap and water; avoid harsh chemicals.

-

Inspect the helmet regularly for cracks, dents, or wear.

-

Replace any damaged suspension systems or accessories immediately.

-

Store in a cool, dry area away from direct sunlight.

Q8: How long does a confined spaces helmet last?

A: Typically, 3–5 years, depending on usage and environmental exposure. Helmets exposed to extreme heat, chemicals, or heavy wear may need replacement sooner. Always follow manufacturer recommendations.

Q9: Can these helmets be used in wet or confined underground spaces?

A: Yes. Many models are water-resistant and suitable for wet or damp environments. For underground work, helmets with built-in or attachable headlamps improve visibility and safety.